The ARM 24 hour Make-a-thon with Bristol Electrical and Electronic Engineering Society

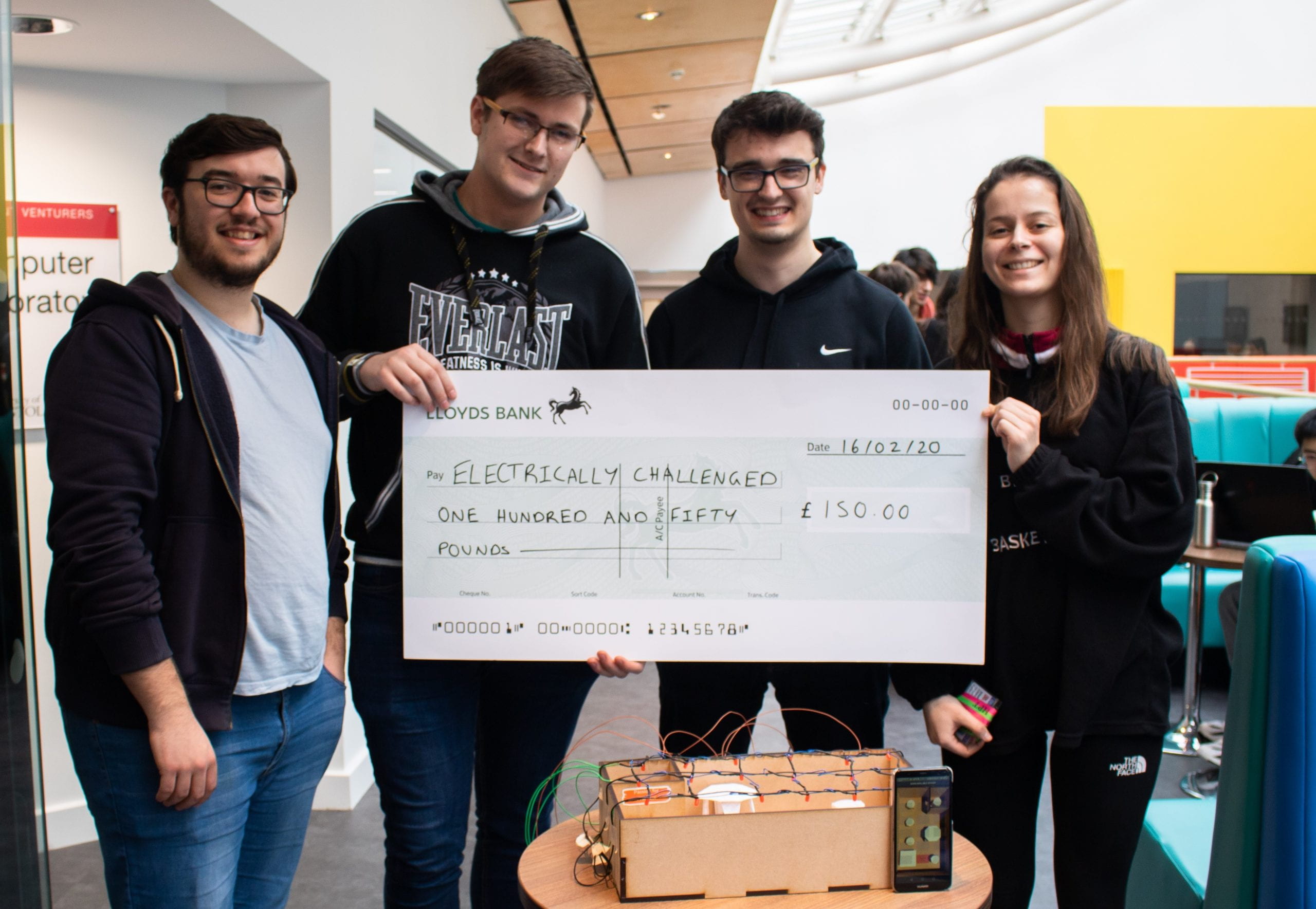

In February over 50 students from across Engineering and beyond spent their weekend getting creative for Bristol Electrical and Electronic Engineering Society’s (BEEES) annual 24 hour Make-a-thon, sponsored by ARM Holdings. Teams had 24 hours to invent and execute a project on the theme of climate change and sustainability.

The Make-a-thon (now in its 12th year), gives students an opportunity to work in multidisciplinary teams, to apply the theoretical knowledge from their courses and to solve industry relevant, real-world problems. Mechanical and Electrical Engineering, undergraduate student Dario Quintero Dominguez explains why the Make-a-thon is so popular: “Real engineering needs opportunities to design and build innovative ideas, which is exactly the opportunity Make-a-thon gives you to complement course learning”.

After 24 hours of high-speed innovation, teams presented to judges from ARM and faculty members Dr Edmund Harbord and Dr Francesco Fornetti. The judging criteria includes creativity, business value, innovation, and functionality.

The winning team made an app that allows workers in warehouses to specify where exactly in a building they want to go, triggering lights on the shortest path to be turned on, helping the factory to reduce energy expenditure on lighting as personnel moved around. They demonstrated this by building a mini warehouse with a grid of LEDS controlled by an Arduino and an ESP32. This was connected to a phone using Bluetooth. Second place went to ‘Dario’s Angels’ who made a physical representation of #teamtrees that connected to a local server. In third place was team ‘This is Fine’ who created an interactive map showing changes in various climate factors around the world.

“It’s an exciting opportunity for us to meet the engineers of the future and each time we visit we are inspired by the creativity of the projects and the teamwork that to complete them in the 24 hour time limit.”

Peter Gorman from ARM said “It’s an exciting opportunity for us to meet the engineers of the future and each time we visit we are inspired by the creativity of the projects and the teamwork that to complete them in the 24 hour time limit. It was fantastic to see so many of the students choose a project that focused on the main theme of climate change and the many creative solutions that they came up with..”

Expand your knowledge

As well as the climate change and environmental sustainability theme, participants were able to enter a ‘free for all’ category. One team in this section made a 3D printed butter onto toast machine, which scored highly with the judges in creativity. Team ‘Blank’ won the prize for being the most multidisciplinary team with team members from across the engineering faculty and geography. Their project explored how much power they could draw from an idle phone in someone’s pocket …. the final measurements were small (in the mA range) but the idea was interesting if it could be scaled!

Alexandru Pop, an Engineering alumnus who now works at ARM said: “It was great to be back in Bristol yet again to witness the creativity unleashed by a tight deadline and unlimited pizza. Each year it evokes fond memories of past UoB hackathons in which I have taken part, and I find this experience greatly inspiring as it reminds me of the passion for making and problem-solving that I share with all the participants.”

The Make-a-thon is always a highlight of our student-led activities. Students have access to the hackspace and excellent support from the technical services team who help them bring their ingenious ideas into reality. From first year to final year, students work together to come up with inspiring and innovative prototypes, which could go on to be tomorrow’s cutting-edge technology.