New research facility to help reduce aircraft noise

As debate continues over the future of air travel, researchers at the Faculty of Engineering are working with industry to mitigate its environmental impacts. One area under investigation is the reduction of jet noise.

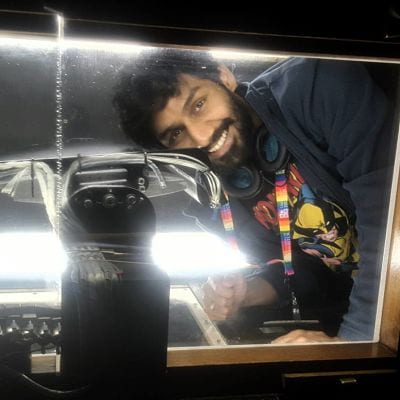

Research Associate Hasan Kamliya Jawahar gained wide-ranging experience during his doctoral studies here at the University of Bristol. He was actively engaged in the design and manufacture of experimental set up and developed new data analysis methods for aeroacoustic studies. With his enthusiasm and multi-topic approach, he was the perfect candidate to set up an exciting new specialist aeroacoustic jet facility. He told us about his work.

“Aerospace engineering is still a fresh and rapidly changing field with the constant demand for sophisticated technological advancements. Aircraft noise, in particular, has been a key environmental as well as health concern for communities with constant exposure. It’s estimated that more than a million people in the UK are exposed to aircraft noise above levels recommended for the protection of health. The new jet facility at the University of Bristol aims to understand the fundamental aerodynamic noise generation mechanisms and to develop more robust and effective methods to reduce aircraft noise.

Because of the pandemic, I faced a number of difficulties during the installation process. There were delays and disruption in the delivery of various components from multiple manufacturers. So, in several instances I decided to improvise. For example, an expensive key component of the project, equipped to hold around 80 microphones, was delayed, so I simplified the design and adapted a cycle rim from Amazon without compromising the high standards of the facility. This determination, despite obstacles thrown up by the ongoing crisis, helped me deliver the project on time. This world-class jet facility is set to drastically enhance the university’s experimental capabilities and to keep us at the forefront of research in the field of aerospace engineering.”

Study at Bristol

Hasan’s PhD subject was ‘Aerodynamic and Aeroacoustics performance of Morphing Structures for aircraft applications’ and he is now exploring the installation effect of jet flows in his current project JINA. He has published 10 journal papers and 16 conference papers. More information about his work can be found on the Explore Bristol Research website.

The JINA project – Jet Installation Noise Abatement

As well as affecting quality of life, productivity and learning, studies have linked aircraft noise with the risk of hospital admissions and mortality due to strokes, coronary heart disease, and cardiovascular disease. In response to more stringent environmental regulations, the aviation industry seeks a better understanding of noise generation mechanisms and more effective ways to reduce noise at source. High bypass ratio turbofans improve the aerodynamic performance of jet engines but they cause the “jet installation effect” – significantly increased noise at low frequencies. The JINA project (Principal Investigator: Professor Mahdi Azarpeyvand) is supported by an EPSRC grant. Its approach is to reduce noise amplification by optimising jet nozzle shape.

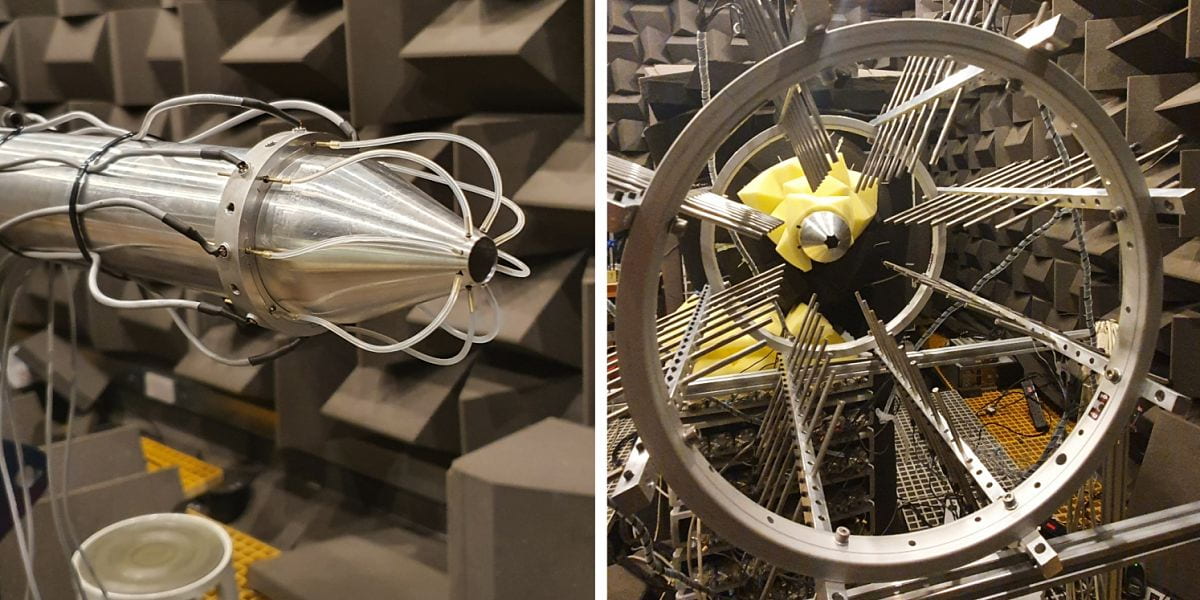

New high-speed jet noise facility – technical info

The new facility is exemplary for fundamental and industrial jet noise, jet installation effects, and flow instability studies. It is capable of Mach numbers between 0.3 and 0.9, using a convergent nozzle with an exit diameter of 1.5” and up to Mach 1.6 for smaller nozzles. The jet setup is situated within the University of Bristol’s anechoic chamber and its flow rate can be controlled using a control valve with high accuracy. Two bespoke in-line silencers condition and silence the flow prior to entering the anechoic chamber and another large third silencer/plenum is used just before the nozzle exit. The facility’s advanced measurement capabilities includes:

- a far-field microphone array with 23 high-fidelity microphones

- near-field acoustics array with 72 microphones that enables near-field acoustic holography used to image the acoustic field in three-dimensional space

- flow measurement capabilities such as hot-wire and PIV

- high-speed flow visualisation capabilities such as schlieren photography.