Emissions-busting morphing blades for helicopters

There’s a huge amount of innovation taking place in the aeronautical sector. From cutting-edge composite materials to hydrogen-powered engines, things in this space are changing rapidly and soon air travel as we know it could look drastically different.

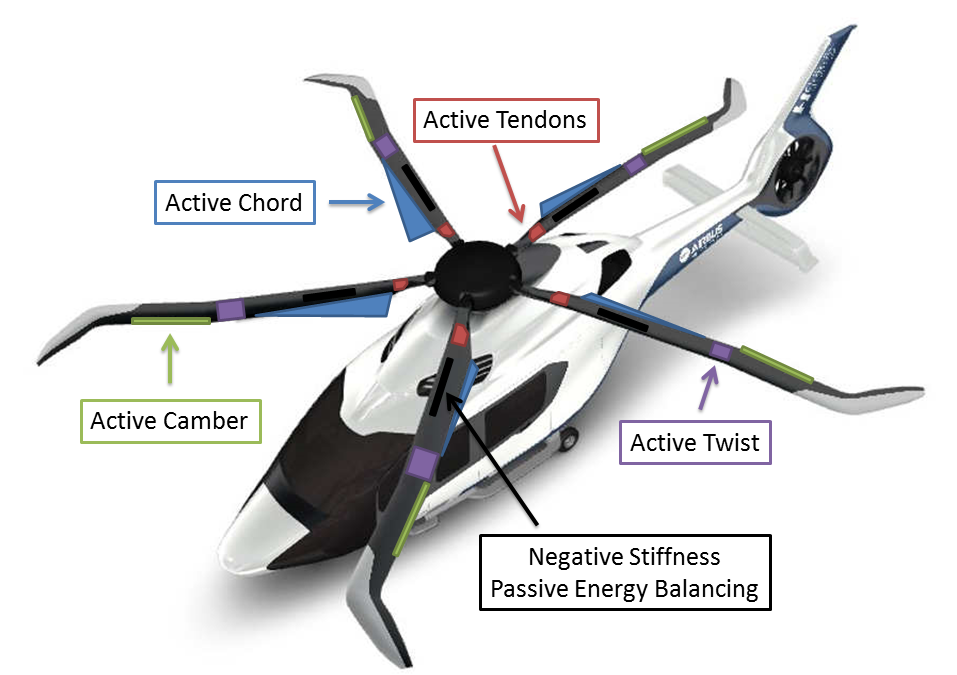

SABRE stands for ‘Shape Adaptive Blades for Rotorcraft Efficiency’. The four-year, €6 million-EU-funded project brought together a consortium of six research institutions from across Europe to develop ground-breaking new helicopter blade designs capable of changing shape in real time to reduce noise, fuel burn and CO2 emissions by up to 11 per cent – a major improvement for what is already such an established technology.

Shape changing aircraft structures are already common on fixed-wing planes. If you’ve ever watched a wing during a commercial flight you’ll see its flaps deploying and retracting during landing and take-off, for example. These changes in wing shape helps the aircraft adapt to different flying conditions, and allow it to change direction as needed.

SABRE’s objective for morphing blades on rotorcraft was largely the same: if each blade can adapt its shape to account for the change in operating conditions instead of fighting against the physics of wind flow and velocity, then helicopters could become quieter, more efficient and use less fuel.

As Ben explains, on a fixed-wing airplane, the operating conditions change relatively slowly – for instance you need less lift as the aircraft slowly gets lighter due to fuel burn, or another example would be the gradual decent and slowing down that happens as you come into land. On a helicopter, however, because the rotor spins so quickly, each blade will see widely varying conditions five to seven times per second. The blades that are flying forward into the wind have a much higher velocity than the retreating blade, and the operating conditions are changing all the time. Different conditions require different blade shapes to optimise performance but traditional helicopters must instead choose a single, fixed design that is a compromise between these very different conditions.

However, with an increasingly urgent climate narrative driving innovation away from fossil fuel-based activities, Ben says that SABRE’s research will have a larger role to play in electrified rotorcraft. “We’ve built the technology to be platform and propulsion agnostic,” he says. “So it could be retrofitted into existing rotorcraft or form the basis of new designs. They can work on a jet engine powered helo or on an electric one. While the morphing devices do require some electrical power to operate, we save much more power than we require. So in the future, with electric rotorcraft, our tech won’t be reducing fuel burn, but instead enhancing flight range and endurance.”

“A wind turbine looks like it’s just doing the same thing all the time,” says Ben. “But in many ways they face the same constantly varying physics as rotorcraft. Wind conditions are always changing, and because each blade sweeps through such a large slice of air, and wind speeds increase the higher above the ground you are, the local air speed at any point along the blade is always changing. These variations again lead to less than optimal performance, and also cause large deformations and fatigue stresses in the blade.” Integrating morphing technology into the blades could therefore mitigate these issues, resulting in longer-lasting structures and more electricity generated by the turbine.

Find out more

The SABRE program has now ended, although the consortium will be looking to continue their progress in upcoming European funded research programs. Ben is now working with a UK project called Fly Zero on conceptual designs of hydrogen-powered aircraft, exploring how morphing could help enable emissions free passenger air travel. However, he says he believes things are looking up for innovation in the rotorcraft industry. “As a young helicopter engineer doing my PhD it was slightly depressing to learn just how much things had plateaued in this field,” says Ben. “But I do think there’s something of a renaissance taking place now, and a renewed willingness to consider new things. SABRE is one small part of that, and I’m really proud of what our consortium has achieved.”