Shaping the future of clean tech with additive manufacturing

Electrical machines will play a major role in breaking our dependency on fossil fuels, but they need to be lighter and more efficient to properly meet our future demands. Researchers at the University of Bristol believe that 3D printing metal components can help.

What happens when innovation is scuppered by a lack of suitable machine parts? Traditionally, this obstacle would involve engineers taking their plans back to the drawing board and trying again, but with the advent of additive manufacturing, also known as 3D printing, engineers are now simply building the items they need themselves – and opening the door to a world of clean tech innovation in the process.

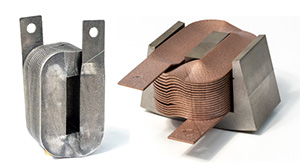

Image credit: Dr. Nick Simpson, The Electrical Machine Works, University of Bristol

One major beneficiary of additive manufacturing is electrical machines – or electric motors – which will play a major role in the global transition away from fossil fuels. Electrical machines are able to convert electricity into mechanical energy but can also convert mechanical energy back into electricity. Take cars, for example. In traditional vehicles, mechanical disc brakes are used to stop the car, and that kinetic energy is simply turned into wasted heat. In electric vehicles (EVs), however, electrical energy is used to make the car move, and then during braking, converts the kinetic energy back into electricity, which is then stored in the battery for further use.

It’s an efficient system, but for electrical machines to properly fulfil the futuristic promises made by tech moguls – think sky taxis and huge EV range – they need to be more efficient still. Of course, you can’t improve on something unless you know what you’re starting with, so one way of measuring this performance is through the system’s power density.

“What we mean by power density is how much power we can get out of a particular volume or mass – and you want your number to be as high as possible,” says Dr Nick Simpson, senior lecturer and UKRI Future Leaders Fellow in Electrical and Electronic Engineering at the University of Bristol. “At the moment, with very high-end systems, you’re looking at about five kilowatts of power per kilogram of machine weight. However, the likes of the APC (Advanced Propulsion Centre) and ATI (Aerospace Technology Institute) have considered future requirements for electrical machines across the aerospace and automotive industries, and they’re looking for more like 20 kilowatts per kilogram by 2030 to 2035. That’s a four-fold increase on what we’ve got today.”

Reducing power waste with 3D printing

As Nick explains, there are multiple factors that influence an electrical machine’s power density – chief among them the amount of power that’s wasted through things like noise, vibrations, friction and, predominantly, heat. Minimising this waste is the main focus of the work that he does with his team in The Electrical Machine Works, and 3D printing offers up a lot of solutions.

Take windings, for example – the electricity-conducting wires that are wound around a magnetic material within an electrical machine. Typically, the insulation coating these wires needs to be made out of a material that can cope with an arduous mechanical winding process, but this material can usually only withstand temperatures of around 180oC, or 200oC for a high-performance machine. Beyond these temperatures a process called life-derating takes place, which reduces the lifespan of the part.

“What we want to do is find a way to enable machines to run hotter with little impact on efficiency.”

“If you’ve designed something to run continuously for 10,000 hours, exceeding this temperature by say, 10oC, could contract that lifespan by 5,000 hours depending on the material,” says Nick. “It won’t destroy it immediately, but it will affect the machine’s achievable power density, as well as increase the need for maintenance cycles and parts replacement. So what we want to do is find a way to enable machines to run hotter with little impact on efficiency.”

A world of opportunity

And this is where 3D printing comes in. “We’re printing windings in an already-wound state, so they can be coated with insulation separately,” says Nick. “This means that the coating doesn’t have to be as flexible as conventional material, which opens up an entirely new range of materials with much higher temperature ratings.”

Expand your knowledge

Using 3D printing also enables better overall thermal management of the machine. “One of the major challenges with electrical machines is that they tend to be cooled from the outside, and there’s a bit of an arduous route for the heat to get through all of the different material layers and out into the cooling system,” Nick explains. “But because we can print very complex geometries, we can actually put coolant fluid directly through our conductors and cool it at source, which is much more effective.”

This higher temperature and better cooling system will ultimately help engineers create smaller, lighter and more power dense electrical machines. Nick can’t yet say how close they are to meeting that four-fold target by 2030-2035, but does verify that “they are getting there”.

“In order to prototype an electrical machine – to produce just one for testing – you’re traditionally looking at tooling-up costs of tens of thousands of pounds.”

In the meantime, the work is opening up a world of opportunity for other disciplines. Because 3D printing enables the production of metals in, as Nick says, “all kinds of weird and wonderful shapes”, engineers are able to integrate terminals, sensors and other tech that turns parts into smart components, “rather than just chunks of metal”.

It also represents major opportunities for ground-up electrical machine innovation. “In order to prototype an electrical machine – to produce just one for testing – you’re traditionally looking at tooling-up costs of tens of thousands of pounds,” says Nick. “Not the case with 3D printing, which lets you try out things you simply couldn’t before because it was so prohibitively expensive.”

Speeding up aerospace innovation

Additive manufacturing also has the potential to ease one of the aerospace industry’s biggest barriers to speedy innovation: time-consuming certification processes. “Everything to do with aircraft goes through a really, really long certification process, and rightly so, as safety needs to be the top priority,” says Nick. “But this means that a graduate could join an aerospace company, for example, and at the end of their entire career have only seen a few things they’ve designed rolled out – that’s how long the process can take.” But 3D printing opens up an avenue for digital-led design, Nick says. “We could be designing and verifying everything digitally. Then imagine taking one of those designs and scaling it for a different application, and for it to be inherently certified because the process of the design and manufacture was already certified, rather than the thing itself.”

This is very much a future scenario, perhaps some 30 years away. However, we can expect to see the applications of Nick and his team’s current work in high-end performance technology within around five years, he estimates.

“We’re all working together to solve a common problem. It’s an inspiring and exciting time to be involved in something that will have such an impact on future technology.”

Of course, additive manufacturing in this way is not without its challenges. “We’re at the very beginning of this work, and its hugely multi-disciplined. We’ve got people from a really wide range of backgrounds working on this project, because every component of it requires so much different expertise,” says Nick. “For example, additive manufactured parts can have quite a rough surface, which can be affected by their processing parameters. So you need a method of either mechanically, chemically or electrically polishing it before you can even get to a place where you can consider the insulation coating. So it’s a very complex, interdisciplinary undertaking.”

But, as Nick says, this is what makes additive manufacturing such an interesting area. “We’re all working together to solve a common problem. It’s an inspiring and exciting time to be involved in something that will have such an impact on future technology.”

Dr. Nick Simpson, The Electrical Machine Works, University of Bristol and John Robinson and Dr. Arun Arjunan, Additive Manufacturing of Functional Materials (AMFM), University of Wolverhampton